ADVANCED 2-Stage Closing System

Stage 1: Side Wall Elimination: inverted angled closing disks provide consistent moist soil replacement and coverage, placing high-moisture soil directly onto and around the seed.

Stage 2: Remove Air Pockets/ Level Seed Bed: A firming leveling press wheel ensures proper seed-to-soil contact for uniform emergence. A chevron pattern on the press wheel provides a stress crack relief in crusting soils and channels water to the root zone area.

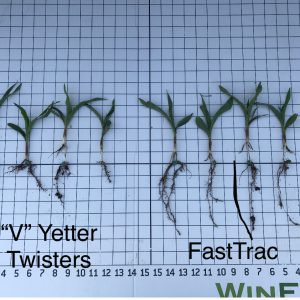

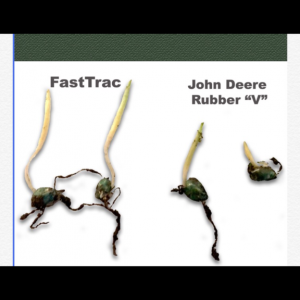

John Deere planters typically are equipped with “V” closing wheels. Ag Focus has developed a superior closing system using an advanced press wheel – FastTrac™.

FastTrac vs. “V” closing wheels

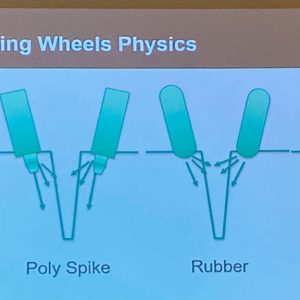

V-shaped closing wheels pinch dry, crusty topsoil back into the trench. That leaves a compacted sidewall and a hard crust. That result is a poor start for your seeds and stunted harvest.

FastTrac gives seeds the best possible opportunity to reach their full yield potential. In our proven two-stage closing process, we bring the zero-pressure press wheel over the top and seal out all the air pockets, getting the seeds off to a fast, uniform start:

1: FastTrac’s double inverted closing disks provide consistent soil replacement and coverage, placing high-moisture soil where it’s needed most, directly around the seed.

2: A chevron pattern creates a stress crack relief in crusting soils and channels water to the roots.

Your result, with FastTrac, is faster seed germination and earlier, more even emergence. And that leads to bigger, more uniform for more tonnage and more consistent sugar content.

Each FastTrac wheel has its own independent suspension, keeping the wheel where it belongs and eliminating free wheel spin.

The tread leaves a line that makes it easy for emerging plants to poke through crusty soil to reach the sunlight and grow and grow and grow.

FastTrac bolts directly on to John Deere planters. It’s simple and durable.

To fertilize as you plant, just order your FastTrac with optional tubes.